In construction, industrial maintenance, and various manufacturing sectors, certain materials have historically played critical roles due to their durability, heat resistance, and insulating properties. Among these is asbestlint, a material composed of asbestos fibers bonded into a tape or ribbon-like format for easy application in insulation, sealing, and fireproofing tasks. While its utility has been widely recognized, asbestlint also carries significant health and environmental risks, primarily due to the fibrous nature of asbestos, which can cause serious illnesses such as lung cancer, asbestosis, and mesothelioma when inhaled. Understanding asbestlint requires more than just knowledge of its applications; it requires comprehension of its chemical and physical properties, safety precautions, regulatory frameworks, alternatives, and proper disposal methods. This article provides a comprehensive exploration of asbestlint, detailing its historical usage, risks, safety measures, modern alternatives, and the legal and environmental considerations surrounding it. By delving into these aspects, readers will gain a well-rounded perspective on asbestlint and its place in modern construction, industry, and health-conscious practices.

1. What is Asbestlint? Composition and Properties

Asbestlint is essentially asbestos tape, designed for high-temperature resistance, sealing, and insulation. It is made by compressing asbestos fibers into a flexible, ribbon-like material that can be applied to surfaces, pipes, boilers, or structural joints. Its fibrous structure gives it excellent tensile strength and heat tolerance, making it ideal for industrial applications where ordinary materials might degrade or fail under extreme conditions. Historically, asbestlint has been used for fireproofing, thermal insulation, and sealing joints in heating and ventilation systems. The material’s main advantage lies in its ability to maintain structural integrity under high heat, moisture, or friction, which is why it became a standard component in construction and mechanical maintenance throughout the 20th century. However, the same fibrous nature that provides these benefits also makes asbestlint extremely hazardous when disturbed, as microscopic fibers can become airborne and easily inhaled.

2. Historical Uses of Asbestlint

Asbestlint has a long history of use, particularly in industrial and construction settings where heat resistance and durability were essential. In the mid-1900s, it was common in boiler insulation, pipe wrapping, furnace lining, and electrical insulation. The flexibility of the tape made it easy to apply to irregular surfaces or tight joints, and it was often preferred over rigid sheets or blankets due to its versatility. In addition to thermal applications, asbestlint was also used in sealing flanges, gaskets, and expansion joints because it could resist compression, heat, and chemical degradation. Its widespread adoption was due largely to its low cost, high performance, and availability, despite emerging evidence during the later decades of the 20th century indicating serious health risks associated with asbestos exposure.

3. Health Risks Associated with Asbestlint

The major concern surrounding asbestlint lies in its potential health hazards. Asbestos fibers are extremely fine and can remain suspended in the air for long periods. When inhaled, they lodge in the lungs and respiratory tract, causing chronic irritation and scarring over time. Prolonged exposure can lead to asbestosis, a condition characterized by stiffening of lung tissue, making breathing increasingly difficult. It is also strongly linked to lung cancer and mesothelioma, a rare but aggressive cancer affecting the lining of the lungs, chest cavity, or abdomen. Even short-term exposure to airborne fibers during installation, removal, or accidental damage can pose risks, making safe handling protocols critical. Understanding the nature of these risks is essential for anyone encountering asbestlint in older buildings, industrial settings, or decommissioned equipment.

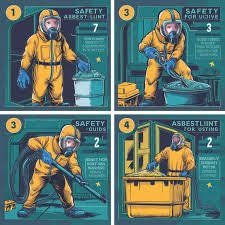

4. Safety Precautions for Handling Asbestlint

Proper handling of asbestlint is not optional; it is essential for preventing exposure and long-term health consequences. Safety measures include wearing personal protective equipment (PPE) such as respirators, gloves, and protective clothing, ensuring adequate ventilation, and using wetting techniques to minimize airborne fibers. It is important to avoid cutting, sanding, or breaking the tape, as these actions release microscopic fibers. In industrial settings, specialized containment procedures and negative-pressure environments are often required to safely manage asbestos-containing materials. Workers must also receive training in asbestos awareness, as knowledge of proper techniques is critical to maintaining safe environments. These safety measures protect not only the individual handling the material but also colleagues and occupants of nearby spaces.

5. Regulations and Legal Considerations

Due to the severe health risks associated with asbestos, the use, removal, and disposal of asbestlint is strictly regulated in many countries. Governments have implemented rules regarding exposure limits, mandatory safety practices, and certified removal procedures. For example, in the European Union, asbestos use is banned, and strict guidelines govern the handling of asbestos-containing materials during renovations or demolitions. Similar regulations exist in the United States under OSHA (Occupational Safety and Health Administration) and the EPA (Environmental Protection Agency), requiring certified removal and disposal. Violating these regulations can result in severe fines, legal liabilities, and long-term health repercussions for affected individuals. Awareness of local laws and compliance with regulatory standards is non-negotiable for anyone dealing with asbestlint.6. Methods of Asbestlint Removal

Removing asbestlint safely requires planning, expertise, and the right equipment. Certified professionals usually perform removal in controlled environments, using negative-pressure containment, HEPA-filtered vacuums, and wetting techniques to suppress fiber release. After removal, materials must be sealed in approved asbestos disposal bags and transported to certified waste facilities. Improper removal can release fibers into the air, endangering workers and nearby occupants. Even small-scale projects, such as renovations in older buildings, should involve consultation with certified asbestos professionals to assess risks and determine safe removal strategies. Proper removal not only ensures compliance with legal standards but also protects health and prevents environmental contamination.

7. Modern Alternatives to Asbestlint

Due to the risks of asbestos, manufacturers have developed safer alternatives that mimic the heat-resistant and insulating properties of asbestlint. These include fiberglass tape, ceramic fiber tape, and mineral wool-based tapes, which offer similar performance without the hazardous fibers. In modern construction and industrial maintenance, these alternatives are widely recommended, particularly in applications involving high heat, friction, or sealing requirements. Replacing asbestos-containing materials with modern substitutes reduces health risks while maintaining functionality, making them essential for renovation, maintenance, and new construction projects. Transitioning to these alternatives is a key aspect of occupational safety and environmental responsibility.

8. Environmental Impact of Asbestlint

Beyond human health, asbestlint poses significant environmental risks. Improper disposal or accidental release can lead to contamination of soil, water, and air, affecting wildlife and ecosystems. Asbestos fibers are highly durable and resistant to natural degradation, meaning they persist in the environment for decades. This longevity underscores the importance of proper handling, disposal, and regulatory compliance. Many governments require asbestos-containing materials to be disposed of in specialized landfills designed to prevent fiber release, ensuring long-term environmental safety. Understanding the ecological implications of asbestlint reinforces the need for responsible management and promotes awareness of sustainable practices.

9. Case Studies: Incidents and Lessons Learned

Several historical cases illustrate the risks associated with asbestlint. Industrial sites in the mid-20th century often used asbestos tape extensively without protective measures, leading to high rates of asbestosis and mesothelioma among workers decades later. Renovation projects in older buildings also demonstrate the danger of accidental exposure during removal or maintenance. These case studies highlight the importance of pre-emptive safety measures, regulatory compliance, and worker education, emphasizing that knowledge and preparation can prevent severe long-term health consequences. Learning from past incidents ensures that modern workplaces handle asbestlint responsibly and protect both employees and the community.

10. Best Practices for Handling Legacy Asbestlint

Many older buildings and equipment still contain asbestlint, requiring careful management. Best practices include:

-

Conducting asbestos surveys before renovations

-

Consulting certified asbestos professionals

-

Implementing strict containment and safety protocols

-

Avoiding unnecessary disturbance of materials

-

Educating workers and occupants about potential risks

These practices minimize exposure, ensure legal compliance, and protect health. Organizations should develop asbestos management plans, periodically review them, and update procedures in line with current safety regulations.

11. The Future of Asbestos Management

The future of asbestos management, including asbestlint, is centered on elimination, substitution, and safe remediation. Many countries continue to phase out asbestos use, develop safer alternatives, and enforce stricter safety standards. Technological advances in monitoring airborne fibers, digital inspection tools, and enhanced protective equipment further improve safety for workers and occupants. Public awareness campaigns and educational programs also contribute to safer handling and management, ensuring that asbestos-related diseases decline over time. Understanding these trends is vital for policymakers, businesses, and workers involved in construction, maintenance, and environmental management.

Conclusion

Asbestlint is a material that reflects both technological ingenuity and significant health risks. While historically valuable for insulation, sealing, and fireproofing, it carries serious hazards that demand careful handling, strict regulatory compliance, and eventual replacement with safer alternatives. Understanding its composition, applications, health risks, safety protocols, legal requirements, environmental impact, and modern substitutes is essential for professionals, renovators, and regulators alike. By following proper procedures, utilizing alternatives, and remaining informed about regulations and best practices, the risks associated with asbestlint can be minimized, ensuring safe workplaces, healthy communities, and environmentally responsible outcomes.

Frequently Asked Questions (FAQ)

Q1: What is asbestlint used for?

Asbestlint is used for insulation, sealing, fireproofing, and thermal protection in industrial, construction, and mechanical applications.

Q2: Is asbestlint dangerous?

Yes. When disturbed, it can release asbestos fibers that pose serious health risks, including asbestosis, lung cancer, and mesothelioma.

Q3: Can I remove asbestlint myself?

No. Removal should be performed by certified asbestos professionals following strict safety protocols to prevent fiber exposure.

Q4: Are there safe alternatives to asbestlint?

Yes. Modern alternatives include fiberglass tape, ceramic fiber tape, and mineral-wool-based tapes, which provide similar heat resistance without asbestos hazards.

Q5: How should asbestlint be disposed of?

It must be sealed in approved asbestos waste containers and taken to certified disposal facilities following local regulations to prevent environmental contamination.

Leave a Reply